Viscosity is a measure of a fluid's internal resistance to flow. It is the most critical fluid property impacting pump performance and selection.

Kinematic Viscosity (υ): The most commonly used unit in pump engineering is mm²/s (centistokes, cSt).

Dynamic Viscosity (μ): Measured in Pa·s or centipoise (cP). The relationship is υ = μ / ρ (density).

Temperature is Decisive: For liquids, Temperature ↑, Viscosity ↓; Temperature ↓, Viscosity ↑. Always determine viscosity at the lowest operating temperature to prevent startup failure or motor overload.

The 20 cSt Rule: For viscosities below 20 cSt, the effect on centrifugal pump performance is negligible. Above 20 cSt, performance must be derated using correction charts.

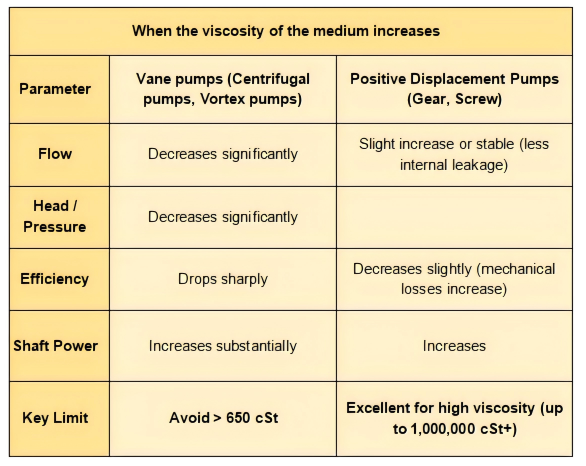

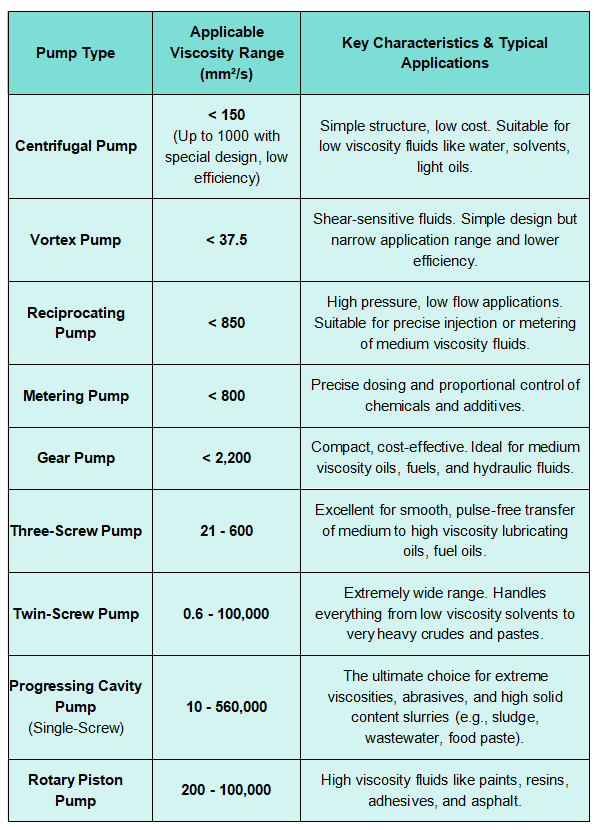

Quick Selection Reference Table:

< 20 cSt: Centrifugal Pump Territory. Most efficient and economical choice.

20 - 150 cSt: Critical Evaluation Zone. Centrifugal pumps require performance correction and may be inefficient. Positive Displacement (PD) pumps become a strong candidate.

> 150 cSt: Positive Displacement Pump Territory. PD pumps (Screw, Gear, Piston) are almost always the most reliable and efficient solution.

Non-Newtonian Fluids (paints, slurries, gels): Avoid centrifugal pumps. Progressing Cavity or Piston Pumps are preferred due to their low shear and handling capabilities.

1.Measure Viscosity Correctly: Always measure viscosity at the actual pumping temperature. A fluid that is thick at room temperature may become thin at process temperature.

2. Check Startup Viscosity: Size the pump and motor for the highest viscosity encountered during cold startup to avoid stalling or tripping.

3. Sealing System Design:

Prefer double mechanical seals or sealless magnetic drive pumps.

Use seal flush systems or heating to prevent fluid solidification.

4.Adequate Power Margin: The motor must be sized to handle the increased torque. A 50-100% power margin over the water duty point is often necessary.

5. Piping & System Design:

Use short, large-diameter suction pipes with minimal elbows.

Consider insulation and trace heating to maintain fluidity.

Install relief valves (mandatory for PD pumps) and recirculation lines.

A Case Study: Using a centrifugal pump for 180 cSt resin resulted in 35% flow, constant motor trips, and seal failures. Switching to a screw pump ensured stable operation, reduced energy costs by 30%, and the investment payback was achieved in under 8 months.

Viscosity is foundational. Ignoring it leads to costly failure. Selecting the right pump technology based on viscosity ensures efficiency and reliability.

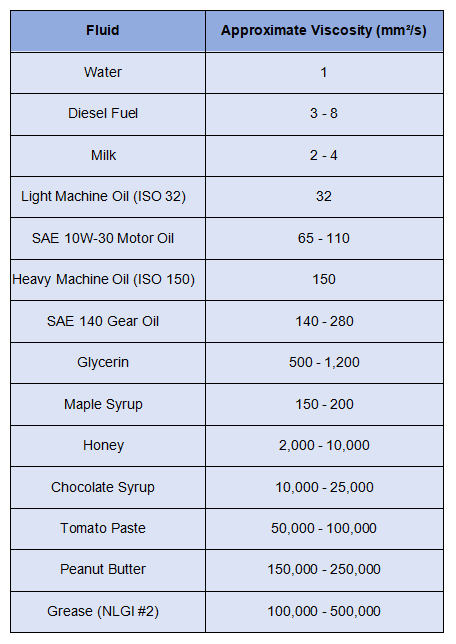

Common Fluid Viscosity Reference Chart (@ 20°C / 68°F unless noted)