Have you ever seen a washing machine shake violently during the spin cycle? Or heard the story of an opera singer shattering a glass with a high-pitched note? These phenomena are caused by a key physics concept: resonance. Today, we’ll explore machine vibrations, how resonance works, and how engineers use this knowledge to diagnose faults.

Machine vibration symptoms (like unusual noise or shaking) don’t always directly point to a specific fault—just as a cough could mean a cold, allergies, or even pneumonia. Similarly, machine vibrations can stem from:

•Worn-out parts

•Misalignment

•Resonance (our main focus!)

Engineers must act like detectives, analyzing vibration frequencies and machine structures to pinpoint the real issue.

(1) Forced Frequencies

Source: Rotating parts (motors, gears, fan blades) generate periodic forces, creating predictable vibration frequencies.

Scale with machine speed (double the RPM, double the frequency).

Disappear when the machine is turned off.

Can be calculated from design specs (e.g., gear teeth × RPM).

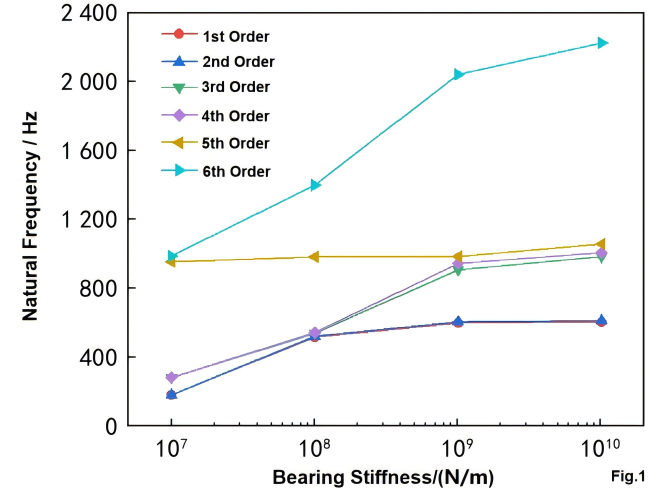

(2) Natural Frequency (Resonant Frequency)

Definition: Every structure (machine base, rotor, pipe) has a "favorite" vibration frequency, like a swing’s natural rhythm.

Formula:

Fn=(1/2π)∙√(K/m)

K = Stiffness (higher stiffness → higher frequency).

m = Mass (higher mass → lower frequency).

Danger Zone: When forced frequency ≈ natural frequency, resonance occurs, amplifying vibrations and risking damage!

What is Resonance?

Resonance happens when forced vibrations match a system’s natural frequency, causing extreme oscillations. Famous examples:

Shattering a glass with sound: Sound waves match the glass’s natural frequency, accumulating energy until it breaks.(Fig.2)

Tacoma Narrows Bridge collapse (1940): Wind vortices matched the bridge’s natural frequency, causing violent swaying.(Fig.3)

Two Types of Machine Resonance

1.Structural Resonance

Affects: Non-rotating parts (frames, pipes, foundations).

Causes: External vibrations (nearby machines, earthquakes) or internal forces.

2.Rotor Resonance

Affects: Rotating shafts (turbines, motor rotors).

Critical Speed: When rotor RPM ≈ natural frequency, vibrations spike.

Solution: Quickly pass through critical speed or redesign to avoid matching.

1.Adjust RPM: Keep forced frequencies away from natural frequencies.

2.Modify Stiffness/Mass: Change design parameters (recall Fn∝√K/m).

3.Add Damping: Use shock absorbers, rubber mounts, or dampers.

4.Vibration Monitoring: Install sensors to detect resonance risks early.

Resonance is both a fascinating physics phenomenon and a potential engineering hazard. By understanding forced frequencies, natural frequencies, and resonance, engineers can design better machines and prevent catastrophic failures.