Standard | API 610 /ISO 5199 |

Shaft | Vertical |

Stage | Single |

Capacity | Up to 400 m³/h / 1760 US gpm |

Head | Up to 100m / 330ft |

Frequency | 50/60Hz |

Temperature | Up to 500℃/1000℉ |

Discharge size | 50 to 250 mm / 2 to 10 inches |

Pressure | Up to 36 bar / 525 psi |

Drive | Motor |

Accessories support

Motor | ABB/Siemens/WEG |

Coupling | TRUMY |

Mechanical seal | John Crane |

Flushing system | Colossus |

Bearing | SKF/FAG |

Electric | ABB/Siemens/DELIXI |

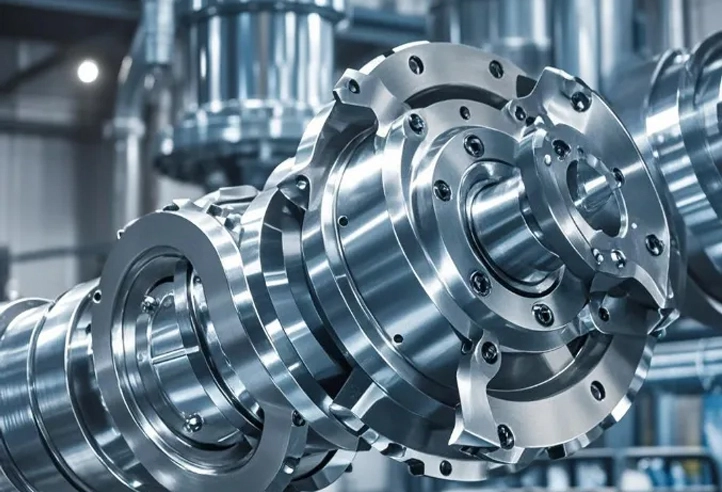

This series of VS4 pumps has carefully considered auxiliary systems such as hydraulic design, rotor rigidity, shaft connection method, guide bearing structure, mechanical seal components, and seal flushing. These refined auxiliary configurations, also key design highlights of the vertical suspended pump, solve the usage and installation defects of pumps in service in the market.

This series of VS4 pumps is designed with modularity, and different specifications of pump components (such as shafts, pump covers, sealing rings, mechanical seals, bearings, etc.) have sufficient interchangeability—an advantage also featured in the oh2 type pump—for easy maintenance in the later stage.

This series of VS4 pumps has become a new generation of heavy-duty process pumps with its unique high efficiency, energy saving, and high reliability, and can be widely used in various industrial fields.

Drainage Sumps

Oily Water Sumps

Lube Oil Supply

Tank Transfer

High-temperature molten salt

Contact With Us:

E-mail: bo@lubor-pump.com

Have a Questions? Call Us:

Add:

No.901 Shuangsheng Road,Lvshunkou District,Dalian

Please contact Hengchuang for your waste management solutions!