Feed pumps play a pivotal role in the functionality and efficiency of boiler systems across various industries, ensuring the continuous feed of water into boilers which, in turn, aids in generating steam. Industrial pumps, including electric pumps and feed pumps, are indispensable in maintaining system pressure and facilitating the smooth operation of these heat-producing giants. Understanding the different types, operational checks, common failures, and repair guidelines associated with feed pumps can greatly enhance the efficiency and longevity of boiler systems. This article provides an in-depth look at these aspects, offering valuable insights for anyone involved in the maintenance or operation of boilers.

Feed pumps are essential components in boiler systems, serving as the linchpin that ensures a continuous flow of water into the boiler. This constant feed is crucial for maintaining the system's pressure levels and ensuring that boilers function efficiently and safely. By facilitating the transfer of water, feed pumps, including specialized types like the Hydrogenation feed pump, help prevent overheating and potential damage caused by low water levels.

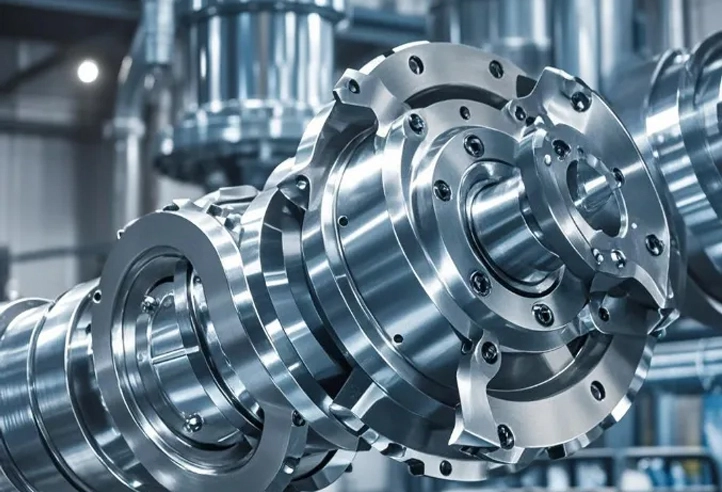

The reliability of feed pumps is bolstered by their design which often incorporates high-strength materials like steel and aluminum for components such as barrels and rods, ensuring durability under high-pressure conditions. This material selection mirrors that found in high pressure pumps and crude oil pumps, where strength and corrosion resistance are paramount.

Boiler systems can utilize a variety of feed pumps, each designed to meet specific operational requirements and system configurations. Common types include centrifugal pumps, positive displacement pumps, and screw pumps—alongside the versatile single rotor pump—which are also used in larger systems such as horizontal split case pumps and vertical turbine pumps. This diversity ensures there is a suitable pump for any application, whether it's for a standard industrial setting or a more customized need.

Choosing the correct type involves understanding the specific requirements of the boiler system, including flow rate, pressure, and power source. For example, electric pumps are often preferred for their efficiency and ease of integration into automated systems, while vertical inline pumps and axial flow pumps offer unique advantages in terms of footprint and flow characteristics.

Regular operational checks are vital to ensure feed pumps are functioning efficiently and to circumvent potential failures. Routine maintenance typically includes checking for leaks, examining the quality of seals – which may be polyurethane or rubber for flexibility and leak prevention – and ensuring that the pump control panel is functioning correctly.

Inspections should also verify that all components are intact and operational, similar to checks conducted on submersible sewage pumps and chemical injection pumps where maintaining integrity under variable conditions is critical. Furthermore, operators should regularly monitor vibration levels and unusual sounds, which can indicate wear or misalignment.

Despite robust design and thorough maintenance, feed pumps may experience common failures such as seal leakage, shaft wear, and impeller damage. Such issues can compromise the performance of the boiler feed pump, leading to reduced efficiency and potential system downtimes.

Seal leakage, often observed in magnetic drive pumps and api pumps, is typically due to wear or material incompatibility. To counteract these challenges, periodic checks and prompt replacement of worn parts are recommended. Additionally, shaft wear can result from misalignment or continual operation under off-design conditions, which are common problems in progressive cavity pumps and slurry pumps alike.

In the event of a failure, ensuring minimal downtime through efficient repair of feed pumps is crucial. Initial steps involve diagnosing the issue correctly, an approach akin to the one used for problems in a condensation pump or mag drive centrifugal pump.

Repairs may range from seal replacement to impeller rebalancing or shaft realignment. Engaging professionals with expertise in horizontal multistage pumps or similar complex systems can enhance repair outcomes and assure system reliability. Furthermore, embracing advancements in pump technology can provide lasting solutions to recurring problems.

Ultimately, maintaining the peak performance of feed pumps in boiler systems necessitates understanding their roles, recognizing the variety of designs available, and adopting rigorous operational and repair practices.

Feed pumps are indispensable to the smooth operation of boiler systems, providing the consistent water feed necessary for safe and efficient boiler operations. By understanding their role, types, operational maintenance, and repair protocols, industries can enhance the lifespan and efficiency of their boiler systems. This comprehensive knowledge, combined with advancements in pump control panel technologies and repair methodologies, ensures that boiler operators can keep their systems running smoothly. Engaging with a variety of pump technologies, from electric pumps to vertical sump pumps, ensures informed decision-making for optimal system performance.