This series of axial flow pumps can be widely used in processes such as evaporation, crystallization, and chemical reactions in industries such as chemical engineering, non-ferrous metals, salt production, and light industry. Its typical application scope, highly valued by axial flow pump manufacturers, is as follows:

1. Phosphate fertilizer plant: forced circulation of media in wet process phosphoric acid concentrator and ammonium phosphate slurry concentrator.

2. Diaphragm caustic soda plant: forced circulation of caustic soda liquid evaporator medium containing NACL.

3. Glauber's salt plant: Forced circulation pump for NA2S04 evaporator medium.

4. Vacuum salt production: Forced circulation pump for NACL evaporative crystallizer medium.

5. Paper mill: forced circulation of the medium in the dark night concentrator.

6. Power plants: forced circulation of ammonium sulfate evaporation crystallizer media in flue gas desulfurization, coking plants, and chemical fiber plants.

7. Light industry: forced circulation of station media such as alcohol concentration, citric acid evaporation, and sugar evaporation.

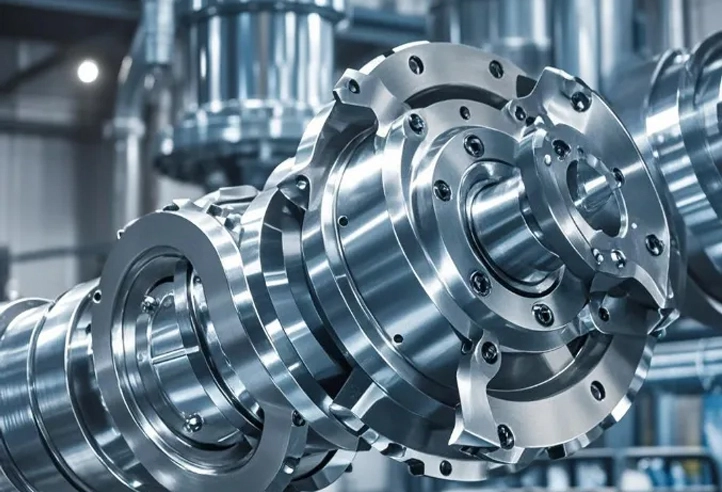

High efficiency in high flow and low head applications

High durability due to its heavy duty construction

Maximum reliability also in high-corrosion applications

Low maintenance costs

High adaptability due to flexible design

Corrosive and abrasive liquids

Solid-contaminated liquids

Chemicals

Evaporation

Crystallization

Mining/minerals

When selecting a pump for industrial applications, knowing the difference between centrifugal and axial flow pumps is crucial. Both serve distinct purposes and cater to specific operational requirements. Below, we will break down their differences and specialized uses.

1. Design & Operation:

Centrifugal Pumps utilize a rotating impeller to generate radial flow, converting kinetic energy into pressure. These are ideal for applications requiring high-pressure output.

Axial Flow Pumps, on the other hand, move fluid parallel to the pump shaft using a propeller-like rotor. This design specializes in high flow rates at low pressure, suitable for handling large volumes of liquid efficiently.

2. Applications:

Centrifugal pumps dominate industries like water treatment, fuel transfer, and chemical processing due to their versatility in managing varying pressures.

Axial flow pumps' uses, on the contrary, are common in irrigation systems, wastewater management, and flood control operations, where high capacities and steady flow are priorities.

3. Why Axial Flow Pumps Stand Out

Designed for heavy-duty tasks, axial flow pumps are excellent when you need to move significant liquid volumes with minimal friction. As a leading axial flow pump manufacturer, LUBOR understands the importance of customization to meet unique operational demands.

LUBOR specializes in producing durable, efficient axial flow pumps for industries worldwide. Our heavy-duty pumps are engineered to handle even the most demanding applications, ensuring smooth operations and optimized performance. Trust LUBOR's expertise as a trusted axial flow pump manufacturer.

Contact With Us:

E-mail: bo@lubor-pump.com

Have a Questions? Call Us:

Add:

No.901 Shuangsheng Road,Lvshunkou District,Dalian

Please contact Hengchuang for your waste management solutions!