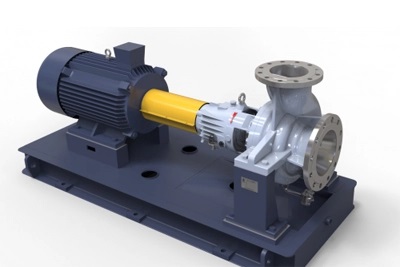

Centrifugal pumps play a vital role in modern water systems, from urban infrastructure to industrial applications. Understanding how these industrial pumps operate can provide essential insights into their efficiency, reliability, and the optimization of water handling operations. This comprehensive guide explores the basic operating principles of centrifugal pumps, their key components, and their functions, as well as applications in water treatment. Additionally, it addresses common issues, troubleshooting tips, and maintenance best practices. Whether you are involved in designing water systems or sourcing components like electric pumps, magnetic drive pumps, or API 610 OH2 centrifugal pumps, this article equips you with the necessary knowledge to make informed decisions.

At the core of any water system, a centrifugal pump raises the pressure of a fluid, ultimately enabling its movement through a system. The pump works on the principle of converting rotational energy, typically from a motor, into energy within a moving fluid. This transformation takes place within the pump's casing, dramatically enhancing the fluid's velocity and pressure, a feature optimized in a centrifugal pump split case.

The principle components involved include the impeller, which is a rotating disc with vanes, and a volute, which is the casing housing the impeller. As the impeller rotates, it spins the fluid from the eye of the impeller (the inlet) to the periphery. In doing so, it imparts kinetic energy to the fluid due to centrifugal force. This energy conversion process is the hallmark of centrifugal pumps, making them highly efficient at transferring fluid from one point to another.

Modern API 610 OH2 centrifugal pumps are designed following this principle, providing robust performance for demanding industrial and water system applications. Their precision engineering ensures consistent flow and durability under high-pressure conditions.

Component | Description | Function |

Impeller | Rotating disc with vanes | Imparts kinetic energy to fluid |

Volute | Casing around the impeller | Converts velocity into pressure |

Seal | Prevents leaks | Maintains pump efficiency and safety |

Motor | Power source | Provides rotational energy to the impeller |

Understanding the major components of centrifugal pumps helps in evaluating their performance and efficiency in water systems. Each component serves distinct functions that contribute to the overall operation of the pump.

The impeller, located at the pump's heart, is crucial for imparting kinetic energy to the fluid. It comes in various types, including open, semi-open, and enclosed designs, each offering distinct advantages depending on the application needs. Closed impellers, for example, provide more efficiency due to reduced flow disorganization.

The volute plays an integral role by converting kinetic energy into pressure energy. This component maximizes energy conversion by strategically channeling the fluid through gradually expanding areas, thus increasing the fluid pressure.

Seals and bearings ensure that the pump operates effectively without unnecessary leakage or friction. Good sealings, such as mechanical seals, prevent the fluid from leaking around the rotating shaft, thereby maintaining the integrity and efficiency of the pump. Bearings ensure smooth rotation and reduce mechanical losses within the system.

API 610 OH2 centrifugal pumps feature high-grade mechanical seals and precisely aligned bearings, making them ideal for continuous-duty water systems and process industries that demand reliability and compliance with international standards.

Centrifugal pumps are indispensable in water treatment processes due to their efficiency in handling large fluid volumes. Water treatment pumps, including high pressure pumps and submersible sewage pumps, are tailored for specific tasks within the treatment plant, ensuring seamless and effective operation.

One of the key applications is in chemical injection pumps, where accurate dosing of chemicals is crucial for maintaining proper water quality. Centrifugal pumps used here are designed for precision and can handle the harsh chemicals typically used in treatment processes.

Another application is found in transfer systems, where oil transfer pumps and feed pumps move water from one stage to another. Collectively, these systems rely on the reliability and efficiency of centrifugal pumps to meet the demanding standards of water treatment facilities.

For high-demand industrial operations, API 610 OH2 centrifugal pumps provide superior hydraulic performance, corrosion resistance, and ease of maintenance—making them a preferred choice for critical applications in chemical processing and municipal water treatment plants.

Despite their widespread use and effectiveness, centrifugal pumps can encounter several challenges. Common issues include cavitation, seal leaks, and mechanical failures, each of which can lead to decreased efficiency and increased operational costs.

Cavitation, characterized by the formation and collapse of vapor bubbles within the pump, can cause significant damage if not addressed. This issue often results from improper pump sizing or operation beyond its specified limits. To troubleshoot, ensure the pump operates within the recommended range and check for any blockages that may hinder flow.

Seal leaks arise due to wear and tear, and addressing them promptly is crucial to maintaining pump integrity. Regular inspection and replacement of seals can prevent fluid leakage and potential damage to surrounding systems.

To avoid performance degradation, high-performance API 610 OH2 centrifugal pumps incorporate advanced hydraulic designs that minimize cavitation risk and extend service life, even under challenging operating conditions.

Routine maintenance is essential for ensuring the longevity and optimal performance of centrifugal pumps. A structured maintenance schedule involving regular inspections, lubrication, and part replacements can prevent malfunctions and minimize downtime.

Firstly, operators should focus on monitoring vibrations and noise levels, as these can indicate potential problems within the pump. High vibration readings often suggest misalignments or imbalances that need correction.

Additionally, lubrication of bearings is essential for reducing friction losses and preventing premature wear. Using appropriate lubricants and adhering to the recommended schedules can maximize the lifespan of pump components.

API 610 OH2 centrifugal pumps are built for maintainability, with easy access to key components, modular designs, and durable materials that reduce downtime and maintenance costs in large-scale water systems.

In conclusion, understanding how centrifugal pumps function and their components is critical for anyone involved in water systems. From basic principles and key components to troubleshooting and maintenance, each aspect plays a role in ensuring efficient and reliable operations.

By following best practices and addressing common challenges, system designers and operators can maximize performance and extend the service life of these essential pumps. When selecting components like boiler feed pumps, process pumps, vertical turbine fire pumps, or API 610 OH2 centrifugal pumps, this knowledge ensures reliable performance across industrial and municipal water applications.