In the expansive world of food processing, rotor pumps are acknowledged for their ability to handle viscous products delicately, making them essential components in maintaining product integrity and hygiene. Among the various types of rotor pumps, the single rotor pump is particularly valued for its simplicity and reliability in handling shear-sensitive materials. Rotor pumps, including the single rotor pump, excel in processing various food materials due to their gentle handling, which preserves the structure and quality of the product throughout the food production process. This comprehensive article will explore the design and operation of rotor pumps, including single rotor pumps, their hygienic features, applications, cleaning methods, and troubleshooting tips, while also considering factors that influence rotor pump price. Whether you are a manufacturer looking for efficient processing equipment or an industry professional seeking to enhance your knowledge, this guide on rotor pumps—especially the single rotor pump—for food processing is packed with valuable insights.

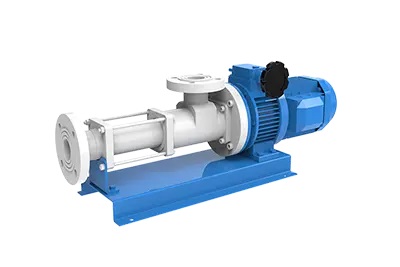

The design and operation of rotor pumps are pivotal to their efficiency in food processing industries. They are uniquely crafted to ensure minimal shear while handling various viscosities, from thin broths to thick sauces. The main components of a rotor pump, such as the rotor and stator housed within a casing that maintains operational pressure, are designed for precision. Among these, the single rotor pump provides a compact and efficient solution, ideal for small to medium flow requirements where reliability is crucial.

Component | Material | Properties |

Rotor & Stator | Stainless Steel, Food Grade Plastics | Non-reactive, corrosion resistant |

Casing | Stainless Steel | Hygienic, durable |

Seals | Food Grade Elastomers | Leak prevention, flexibility |

The pumps operate on a positive displacement mechanism, which allows for a consistent flow regardless of the pressure conditions on the production line. Unlike centrifugal pumps or axial pumps, rotor pumps, especially the single rotor pump, ensure that shear-sensitive products are handled without compromising their quality. This characteristic is crucial when dealing with sensitive ingredients such as creams or dairy products. Electric pumps fitted with variable speed drives can enhance the control over flow rates, optimally adjusting to the requirements of different stages of the food processing cycle, further highlighting the versatility of the single rotor pump in food production scenarios.

Ensuring hygiene is a top priority in the food processing industry, and rotor pumps, including the single rotor pump, are specifically designed with features that adhere to stringent sanitary standards. Their construction minimizes crevices where bacteria could accumulate, supporting quick and thorough cleaning. Smooth surface materials, such as polished stainless steel, ensure minimal residue retention.

To maintain these standards, rotor pumps typically comply with 3A sanitary standards and EHEDG guidelines. They often incorporate features like clean-in-place (CIP) systems that allow internal surfaces to be sanitized without disassembly, reducing downtime and maintaining operational efficiency. Furthermore, magnetic drive pumps present no risk of leakage from seals, as they use magnetic coupling to transmit torque, adding an extra layer of hygienic assurance.

Rotor pumps are versatile and have broad applications across various segments of the food processing arena. They are predominantly used in dairy processes to handle cheese curds and yogurt due to their ability to manage shear-sensitive materials. In addition, the single rotor pump is particularly effective in smaller production lines where precise dosing and gentle handling are required.

These pumps also excel in confectionery for transporting syrups and chocolates without altering their textural properties. In beverage production, they aid in maintaining the integrity of juices and pulps, ensuring that the final product meets precise quality standards. Rotor pumps, including single rotor pumps, are significant in meat processing for emulsified products and in bakeries for delicate fillings and batters.

For niche applications, such as in spice and sauce production facilities, rotor pumps maintain product consistency and flavor profiles, which standard industrial pumps might compromise. This adaptability, along with the efficient performance of single rotor pumps, showcases their critical role in increasing efficiency and preserving product quality across diverse food processing contexts.

Cleaning rotor pumps, including single rotor pumps, is straightforward due to their hygienic design and the availability of CIP systems. CIP processes allow high-temperature flushing with water and cleaning agents to effectively reach all surfaces within the pump, significantly reducing downtime and enhancing productivity.

Besides CIP, manual cleaning remains an option. Traditional disassembly allows thorough inspection and cleaning, ensuring pump performance is maintained. Hybrid cleaning systems that combine CIP with manual checks provide comprehensive maintenance coverage, particularly useful for single rotor pumps in high-demand processing lines.

Innovative cleaning solutions continue to evolve, with manufacturers increasingly focusing on eco-friendly cleaning agents that reduce chemical residues. Proper cleaning protocols are pivotal in sectors where flavor contamination could lead to significant quality issues, emphasizing the importance of meticulous maintenance.

Even the most reliable hardware, including rotor pumps and single rotor pumps, may encounter operational challenges. Common issues include excessive noise, reduced flow rates, or leakage, which can disrupt processes. Identifying the root cause is essential for effective troubleshooting.

Issue | Possible Cause | Solution |

Excessive Noise | Air entrainment, cavitation | Check for air leaks, ensure proper lubrication |

Reduced Flow Rates | Blockage, wear | Inspect for debris, replace worn components |

Leakage | Seal failure | Replace seals, inspect for alignment issues |

For complex issues, partnering with experienced slurry pump manufacturers or service providers ensures access to technical expertise to diagnose and resolve problems effectively. Proactive maintenance, including regular inspections and timely component replacements, is highly recommended to minimize unscheduled downtime.

Rotor pumps for food processing, including single rotor pumps, stand at the forefront of ensuring efficient, high-quality output in the food industry. From their design and operation to hygienic features, versatile applications, effective cleaning methods, and robust troubleshooting capabilities, these systems meet a wide array of processing needs. Utilizing advanced materials and adhering to rigorous manufacturing standards, they offer both reliability and innovation.

The ability of single rotor pumps to handle sensitive ingredients delicately while meeting hygiene standards ensures they remain indispensable in the industry. For businesses seeking to optimize processes, selecting the right rotor pumps and maintaining them correctly can significantly boost productivity and ensure compliance with food safety standards. With ongoing advancements in pump technology, single rotor pumps continue to evolve, addressing traditional challenges and setting new benchmarks in food processing efficiency.