Vertical pumps are widely used in water supply, petrochemical, process industries, and special working conditions, covering applications from normal to high temperatures, low to high pressures, and handling clean, corrosive, or flammable fluids, a range expertly manufactured by leading vertical inline pump manufacturers. Although horizontal pumps are more common in refineries and boiler feedwater systems, vertical pumps remain the preferred choice for many applications due to their low cost, lightweight, and compact structure.

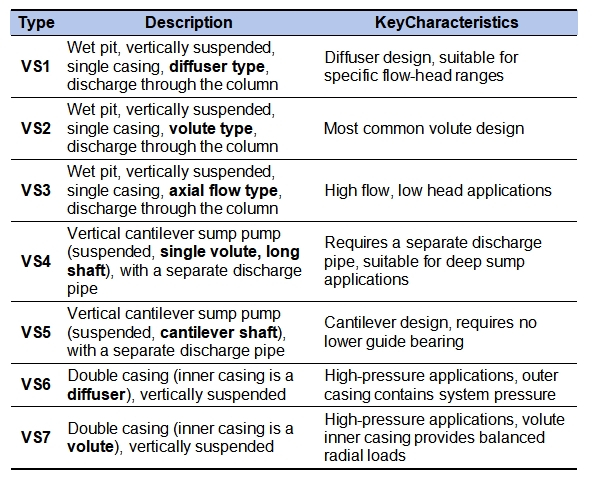

Vertical Suspended (VS) Pump Types and Characteristics

Key Consideration: For all VS pumps, the static head and friction loss of the column must be carefully calculated to avoid underestimating the required discharge pressure.

_Pump_Types_and_Characteristics.png)

Flow Rate Selection: The rated flow should be within 80%–110% of the Best Efficiency Point (BEP), and the performance curve should extend to at least 135% of the BEP flow.

Dynamic Assessment: Long-shaft pumps require torsional vibration analysis. It is recommended to maintain a 15%–20% separation margin between the natural frequency and the operating speed harmonics.

Thrust Bearings: Vertical pumps experience significant thrust loads, necessitating reinforced thrust bearing design. If no integral thrust bearing is used, a rigid adjustable coupling must be employed.

Medium and large VS pumps are prone to resonance due to their flexible structure and require detailed dynamic validation.

X-Y directional vibration probes and keyphasors for each bearing.

RTD temperature sensors for all bearings.

Two axial displacement probes per shaft are recommended.

Configuration may be simplified for small pumps.

A dual flush system (e.g., external clean fluid + pumped liquid) with automatic switching is preferred.

Typical Application: Seawater pumps must be configured with a dual flush system (industrial water + seawater) to ensure continuous operation during external clean fluid interruption.A single external flush solution is not acceptable, as its failure could lead to a full shutdown.