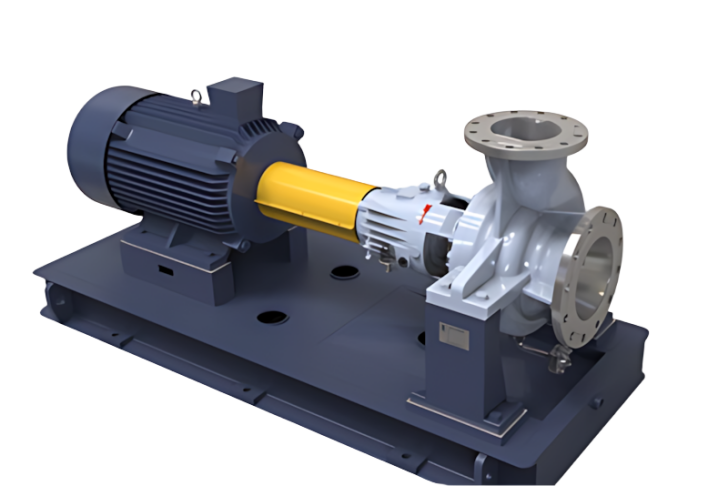

In the oil, gas, and petrochemical industries, centrifugal pumps act as the "heart," continuously transporting various media. The API 610 standard (equivalent to ISO 13709) is the core specification ensuring this "heart" remains robust and reliable. Developed by the American Petroleum Institute (API), it is globally recognized as the highest industry benchmark for the design, manufacturing, and testing of centrifugal pumps.

API 610 is an international standard for centrifugal pumps used in the petroleum, petrochemical, and natural gas industries. It aims to ensure the safe, reliable, and efficient operation of pumps under harsh conditions such as high temperature, high pressure, corrosion, and flammability. It is not only a technical specification but also a culmination of industry best practices.

For professionals needing access, you can download API 610 from authorized sources for complete specifications.

1. High Reliability: Maintains stable performance even under extreme conditions.

2. Stringent Safety Standards: Ensures the safety of equipment and personnel through material selection and structural design.

3. Energy Efficiency: Emphasizes optimized energy utilization, reducing long-term operational costs.

4. Comprehensive Testing Requirements: Every pump undergoes rigorous performance testing to ensure compliance.

5. Customization Compatibility: Allows for tailored designs based on specific operational needs while maintaining standard compliance.

6. Versatile Applicability: Covers a wide range of applications, including upstream extraction, midstream transportation, and downstream refining.

API 610 is updated approximately every five years. The 12th edition, released in 2021, focuses particularly on enhancing reliability and optimizing maintainability. Major changes include:

New Appendix O: Provides guidelines for the design, selection, and testing of "special-purpose centrifugal pumps" (e.g., ultra-high head, high-power pumps).

Introduction of API RP 691: Incorporates risk-based machinery management concepts to improve equipment lifecycle management.

Updated Bearing Selection Criteria: Includes energy density limits and oil temperature control to enhance bearing system reliability.

Enhanced Baseplate and Piping Design: Improves overall rigidity and vibration resistance of pump units.

Clarified NPSH Margin Definition: Emphasizes using "NPSHi (Incipient NPSH)" instead of the traditional "3% head drop" method to more effectively avoid cavitation risks.

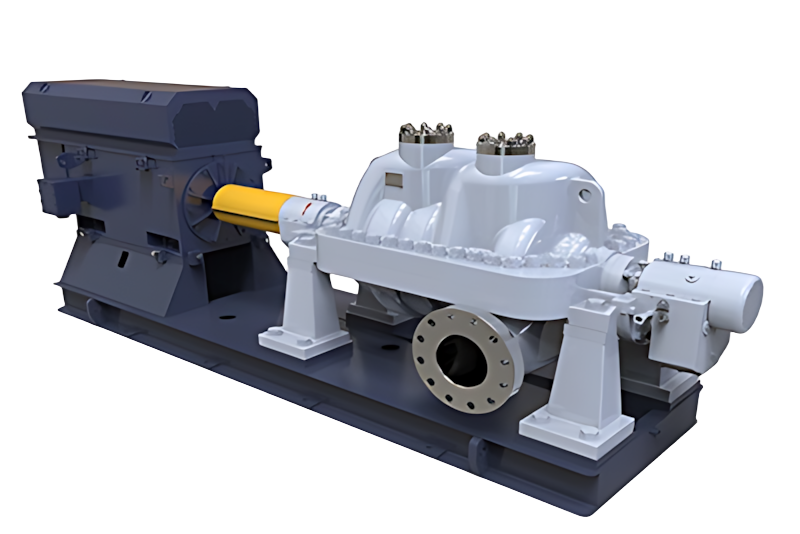

Although these pumps account for only about 1% of all pumps in use, they present significant technical challenges. Typical examples include:

Rocket engine turbopumps (e.g., the F-1 pump);

High-pressure injection pumps (pressure up to 500 bar);

Ethylene plant pipeline pumps;

High-pressure boiler feed pumps;

Large-scale refinery feed pumps (without standby units).

API 610 is not just a standard for pump design and manufacturing—it is the cornerstone of safe, reliable, and efficient operation in the oil and gas industry. The release of the 12th edition in 2021 further addresses the industry’s urgent need for enhanced reliability in high-energy pumps, providing more scientific and precise guidelines for pumps under special conditions.

Built for the harshest conditions, API610 pumps are highly standardized, with reliability and durability as the top priorities.