| Corrosion Type | Key Causes | Vulnerable Materials | Prevention Measures | Critical Parameters |

| Stress Corrosion (SCC) | Cl⁻ + O₂ environment | 304, 316 (low-resistance) | - Use duplex steels (e.g., 2205/2507) - Control stress (welding/assembly) - Add inhibitors (nitrates/Na₂SO₃) | Cl⁻ > 200 ppm O₂ > 1 ppm Temp > 60°C |

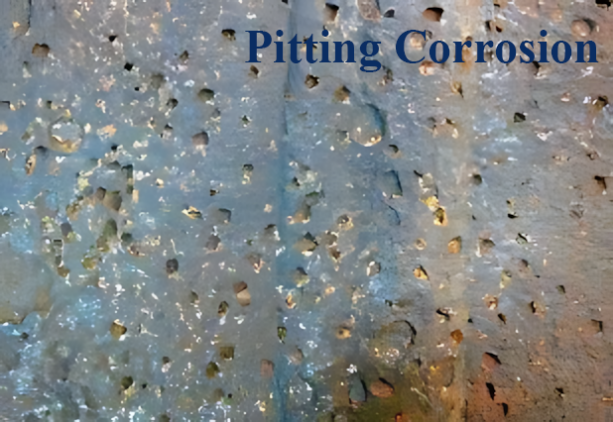

| Pitting Corrosion | Stagnant Cl⁻ solutions (pit nucleation) | Mo-free grades (e.g., 304) | - Add Mo/N/Si (e.g., 316L, 904L) - Cathodic protection - Reduce Cl⁻ concentration | Cl⁻ > 1000 ppm pH < 4 |

| Crevice Corrosion | Cl⁻ accumulation in gaps | All (worse in low-Mo grades) | - Eliminate crevices (design) - Use high-Mo alloys (254SMO) - Sealants/gaskets | Cl⁻ > 500 ppm Stagnant flow |

(At 50–70°C, pH 2–6)

| Cl⁻ Concentration | Recommended Material | Alternative | Max Temp |

| <200 ppm | 304 | 430 (ferritic) | 80°C |

| 200–1000 ppm | 316L | 2205 (duplex) | 70°C |

| 1000–5000 ppm | 904L | 254SMO (super austenitic) | 60°C |

| >5000 ppm | 2507 (super duplex) / Titanium | Hastelloy C-276 (Ni-alloy) | 50°C |

The corrosion resistance mechanism of stainless steel is based on the passivation film theory. This means that an extremely thin, robust, dense, and stable Cr-rich passivation film forms on its surface—an essential property specified by api pump standards—preventing oxygen atoms from further penetration and oxidation, thereby achieving rust and corrosion resistance.

Many people believe that "stainless steel does not rust." However, this is a misconception—stainless steel can indeed rust under certain conditions. By gaining an intuitive understanding of various types of stainless steel corrosion, we can take appropriate measures to minimize losses when corrosion occurs. Most corrosion damage to stainless steel manifests as localized corrosion, with common types including stress corrosion, pitting corrosion, and crevice corrosion. For details, please refer to the table below.