T304 Stainless Steel: Suitable for chloride concentrations 0–200 mg/L.

T316 Stainless Steel: Tolerates chloride levels <1000 mg/L.

T317 Stainless Steel: Resists chloride concentrations <5000 mg/L.

Note: Chloride content in hydrostatic test water must not exceed 25 mg/L for stainless steel/nickel alloy pipelines.

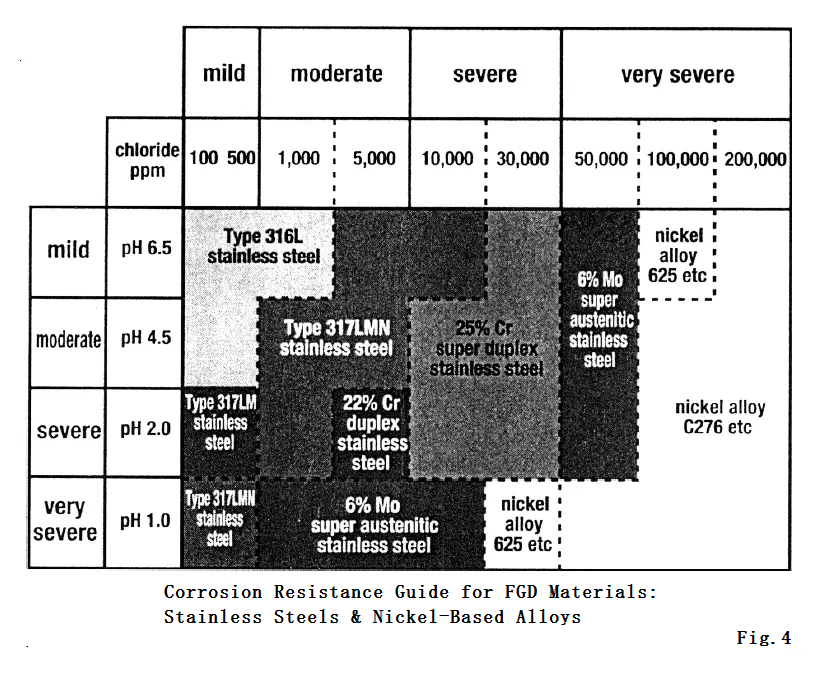

Refer to Figure 1:

Low chloride & low temp: 304 (red zone in charts).

High chloride & high temp: Pure titanium (green zone).

A simplified hierarchy for chloride resistance (low to high):

304 < 316L < 904L < 254SMO < Pure Titanium (TAI)

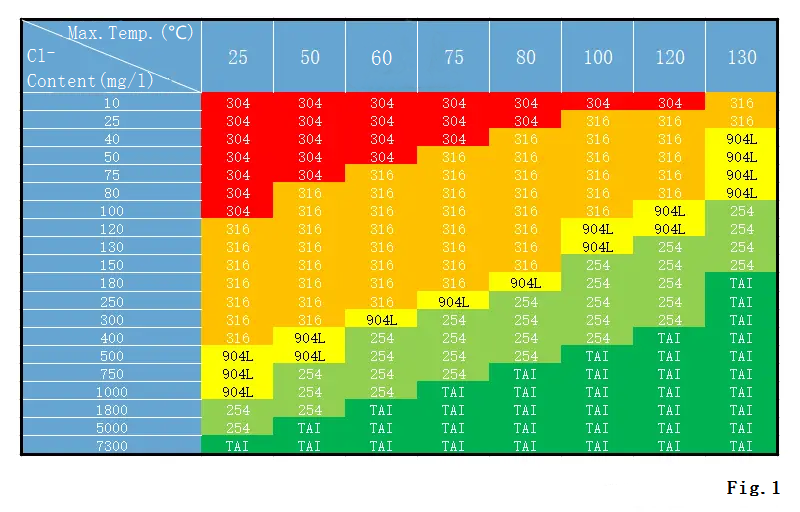

The Pitting Resistance Equivalent (PRE) number reflects a material's resistance to chloride-induced pitting corrosion.

Refer to Fig.2:

2101/2304/2205/2507 duplex steels outperform 316L, with some matching super austenitics:

2507 ≈ 254SMO

2205 ≈ 904L

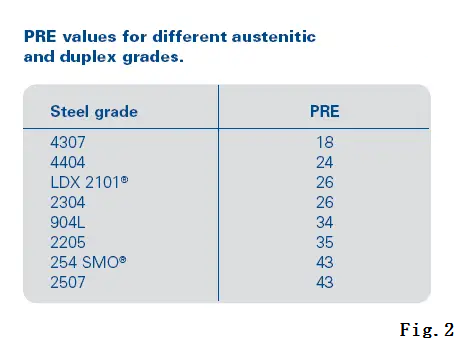

Refer to Fig.3:

316L stainless steel demonstrates significantly inferior chloride pitting corrosion resistance compared to 254SMO. At 60°C, 316L withstands less than 200 ppm chlorides, while 904L resists 8,500 ppm and 254SMO endures up to 15,000 ppm chloride concentration.

At 50-70°C, simply match materials to pH and chloride concentration requirements.