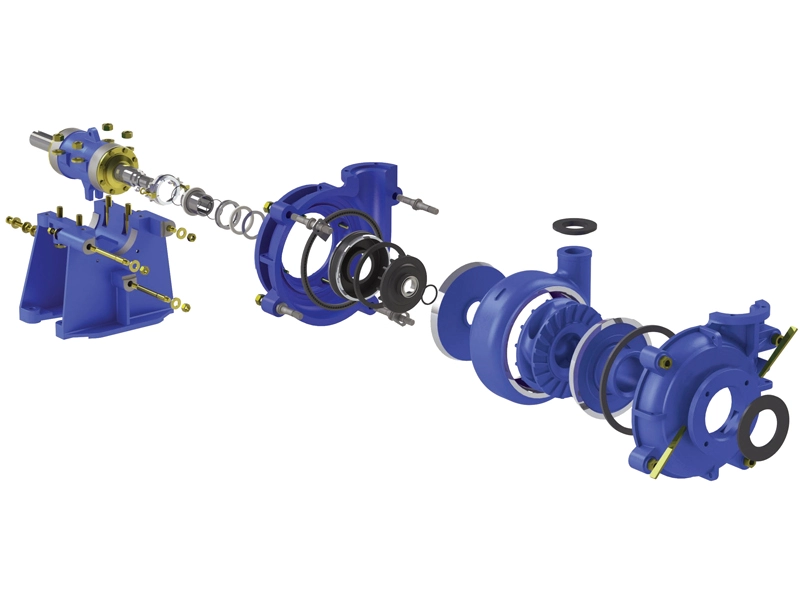

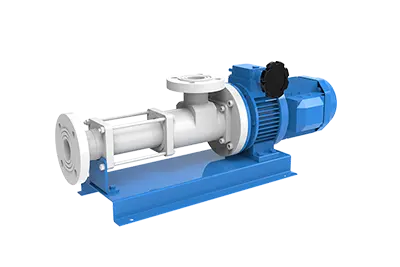

A vertical magnetic drive multistage pump is a specialized type of pump designed for transferring liquids efficiently, especially in high-pressure applications. This type of pump uses a magnetic drive system, eliminating the need for traditional seals and offering numerous advantages in terms of reliability, safety, and efficiency. The vertical magnetic drive multistage pump is used in various industries, including chemical processing, water treatment, oil and gas, and HVAC systems. This article explores the key applications of the vertical magnetic drive multistage pump, its benefits, and how it is suited to demanding environments.

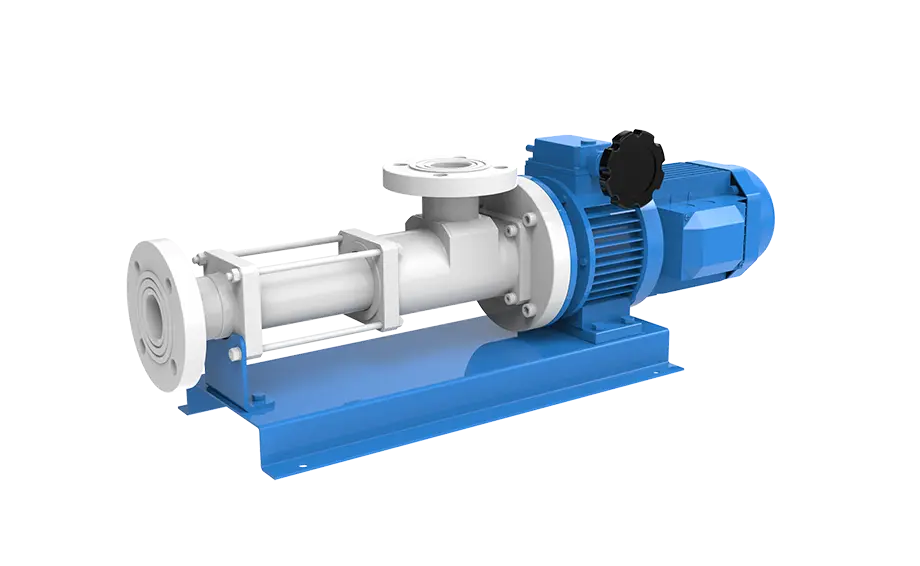

Chemical and Pharmaceutical Industries

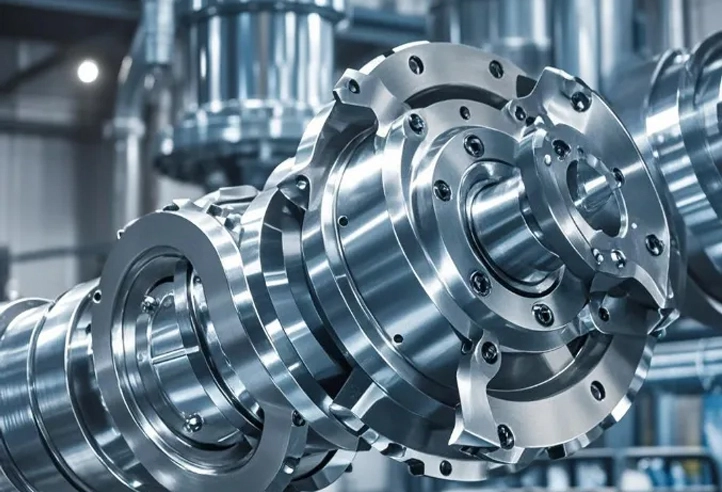

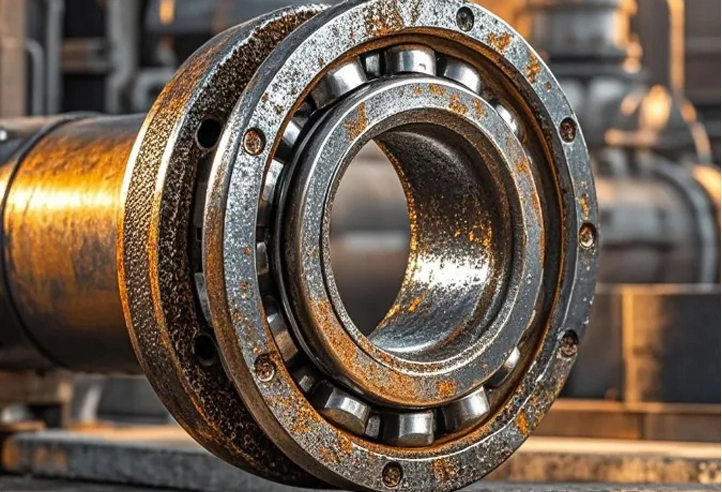

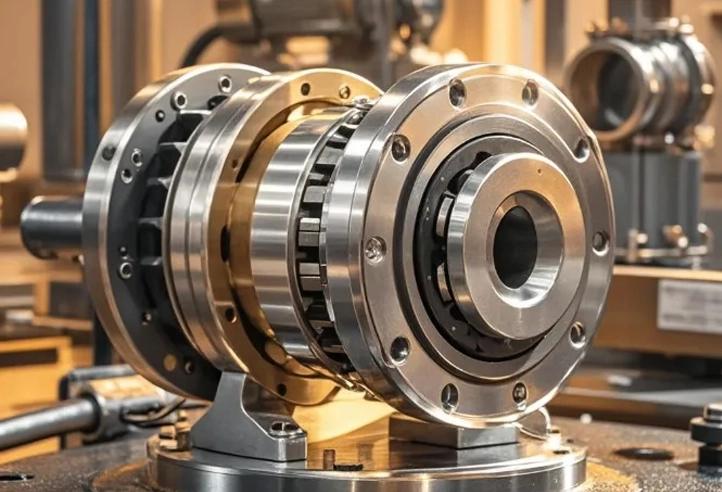

In the chemical and pharmaceutical industries, the vertical magnetic drive multistage pump is invaluable due to its ability to handle hazardous and corrosive fluids safely. The pump’s magnetic drive eliminates the need for mechanical seals, which are prone to leakage and contamination. This feature is particularly important when transferring aggressive chemicals or sterile liquids. The vertical magnetic drive multistage pump ensures precise flow control and prevents leakage, making it ideal for maintaining product quality and ensuring a safe working environment in chemical and pharmaceutical plants.

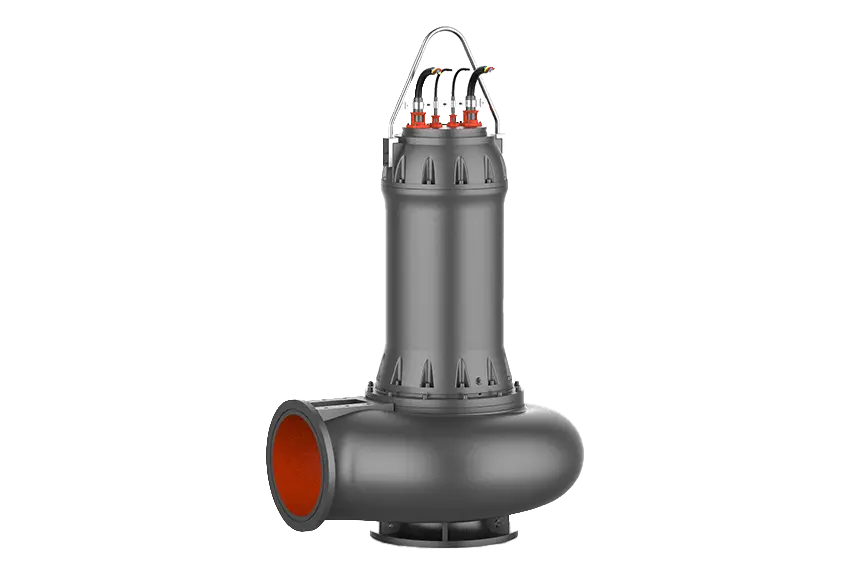

Water Treatment Systems

Water treatment plants often require pumps that can deliver high-pressure performance while being resistant to wear and corrosion. The vertical magnetic drive multistage pump is ideal for such applications, providing reliable and efficient pumping of water, chemicals, and other treatment solutions. These pumps are capable of handling varying flow rates and high-pressure demands, which makes them essential for systems like reverse osmosis, desalination, and wastewater treatment. The efficiency and reliability of the vertical magnetic drive multistage pump help minimize downtime and reduce the operational costs of water treatment systems.

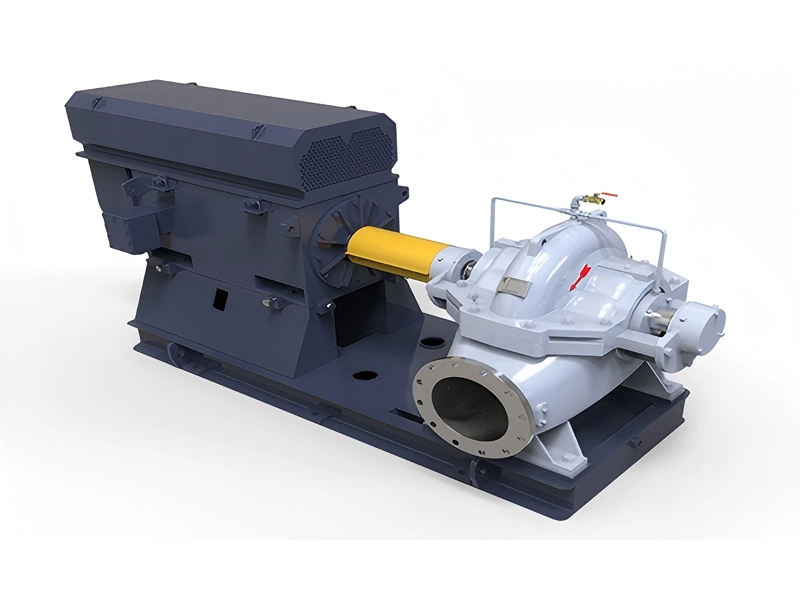

Oil and Gas Industry

The vertical magnetic drive multistage pump plays a crucial role in the oil and gas industry, especially in applications where safety and precision are paramount. In this sector, the pump is used for transporting a variety of fluids, including oil, gas, and drilling fluids. The absence of mechanical seals in these pumps reduces the risk of leaks, which is vital in environments where hazardous materials are handled. Additionally, the vertical magnetic drive multistage pump ensures stable and consistent performance, even under high-pressure conditions typically found in drilling operations, refining processes, and pipeline transportation.

HVAC Systems and Industrial Cooling

HVAC systems and industrial cooling applications often require high-efficiency pumps capable of operating at various flow rates and pressures. The vertical magnetic drive multistage pump is designed to provide optimal performance in such environments. It is commonly used in circulating cooling water, chilled water systems, and heat exchangers. The pump's ability to provide steady pressure and control flow makes it ideal for maintaining the efficiency of large-scale heating and cooling systems. Additionally, the magnetic drive feature ensures that the pump operates without leakage, which is crucial for maintaining system integrity and reducing maintenance costs.

| Feature | Vertical Magnetic Drive Multistage Pump |

|---|---|

| Efficiency | High |

| Safety | Excellent (No leakage) |

| Durability | High |

| Industry Applications | Chemical, Pharmaceutical, Oil & Gas, HVAC |

The vertical magnetic drive multistage pump is a reliable, efficient, and safe solution for various industrial applications. Its ability to handle high-pressure conditions, transfer hazardous fluids safely, and minimize maintenance makes it a preferred choice in industries such as chemicals, pharmaceuticals, oil and gas, and water treatment. The magnetic drive technology ensures leak-free operation, reducing the risks associated with traditional pumps. With its high performance, durability, and safety features, the vertical magnetic drive multistage pump is essential for industries that require precision, reliability, and efficiency in fluid handling.

English

English