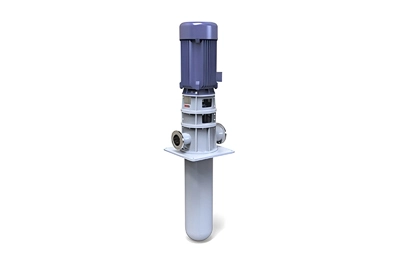

An API standard pump is a high-quality industrial pump that meets the standards set by the American Petroleum Institute (API). These pumps are essential in industries such as oil and gas, petrochemical, and chemical processing, where reliability, safety, and performance are critical. Designed to handle various demanding applications, an API standard pump offers several benefits over conventional pumps. This article will explore the key advantages of the API standard pump, including its performance, durability, safety, and compliance with industry standards.

One of the most significant advantages of an API standard pump is its superior performance. These pumps are specifically engineered to handle high-pressure, high-temperature, and heavy-duty applications, making them ideal for industries such as oil and gas, refineries, and chemical plants. The API standard pump provides efficient fluid handling in harsh environments, ensuring smooth and reliable operation even under extreme conditions. Its design optimizes flow rates, reduces energy consumption, and minimizes maintenance requirements, making it an efficient choice for long-term operations.

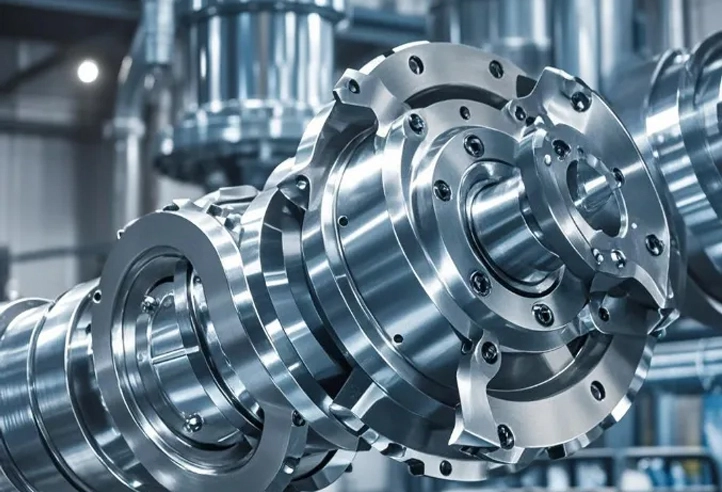

Durability is a critical factor when selecting pumps for industrial applications. The API standard pump is designed for maximum durability, using materials and construction techniques that ensure long service life in demanding environments. These pumps are built to withstand corrosive fluids, abrasive particles, and high operating pressures, offering reliability and low downtime. The API standard pump's robust construction reduces the likelihood of breakdowns and extends its operational lifespan, making it a cost-effective investment in the long run.

Safety is a top priority in industries dealing with hazardous materials and high-risk environments. The API standard pump is manufactured to meet stringent safety standards set by the American Petroleum Institute. These pumps are equipped with safety features such as leak detection systems, pressure relief valves, and fail-safe mechanisms that minimize the risk of accidents and ensure safe operation. Compliance with API standards helps prevent leaks, spills, and other safety hazards, making the API standard pump an essential component for maintaining safety in industrial facilities.

An API standard pump is fully compliant with the API 610 standard, which specifies the design, materials, and testing requirements for centrifugal pumps in the oil and gas industry. This standard ensures that the pump meets the high-performance criteria necessary for critical operations. By choosing an API standard pump, companies ensure that their equipment adheres to the best practices in the industry, guaranteeing reliability and operational excellence. Additionally, API certification provides confidence that the pump has undergone rigorous testing to meet quality and performance expectations.

| Feature | API Standard Pump |

|---|---|

| Performance | Superior |

| Durability | High |

| Safety Standards | Excellent |

| Industry Compliance | Full API 610 Compliance |

The API standard pump is a reliable, high-performance, and durable solution for industries requiring efficient fluid handling under challenging conditions. With its superior performance, enhanced durability, strict safety features, and compliance with industry standards, the API standard pump ensures safe and efficient operation. Choosing an API standard pump guarantees that your equipment meets the highest industry benchmarks, providing long-term value and reducing the risk of operational failures. For industries involved in high-risk and demanding applications, the API standard pump is an essential choice for optimal performance and safety.