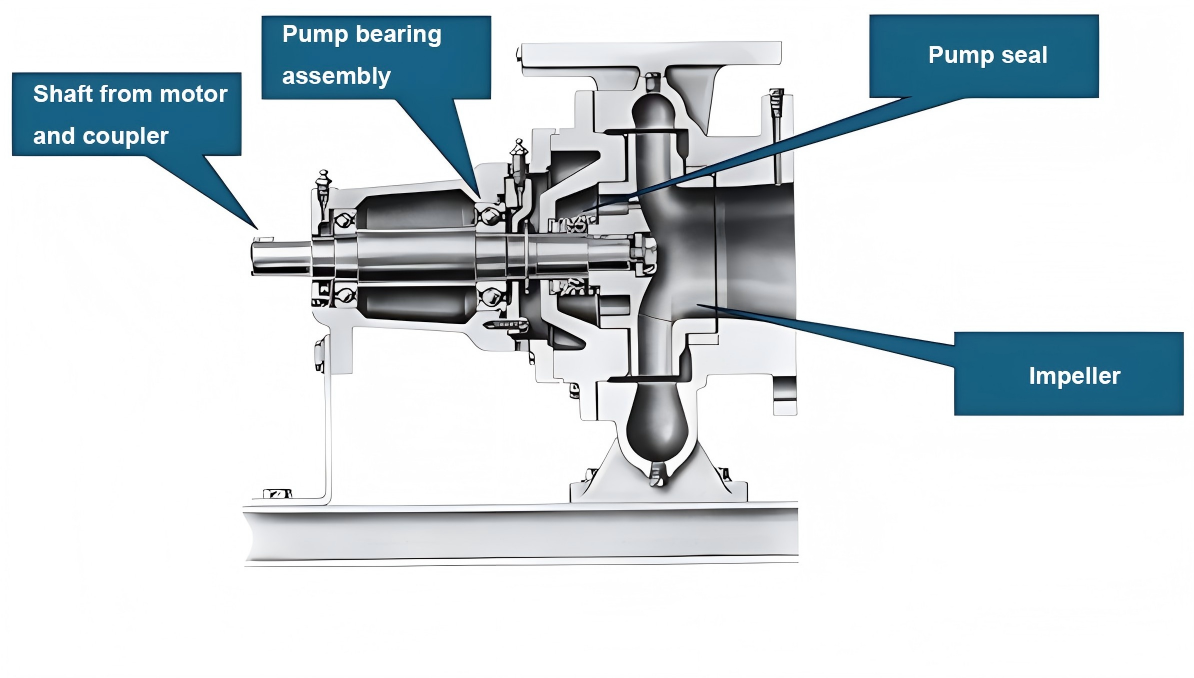

In industrial pumping systems, seals are often the most overlooked yet critical components. They act as the pump's "guardian," silently ensuring system stability. When seals fail, the entire pump system's efficiency, reliability, and cost are directly affected.

The primary mission of seals is "bi-directional protection":

1.Prevent Leakage: Stop the pump's internal fluid (especially hazardous, expensive, or corrosive liquids) from leaking out, avoiding resource waste, safety incidents, and environmental pollution.

2.Prevent Contamination: Block external contaminants like dust and air from entering the pump, ensuring the purity and quality of the transferred fluid. This is crucial for industries like food, pharmaceuticals, and chemicals.

Furthermore, seals help maintain the pump's optimal operating pressure and temperature by reducing internal friction, thereby enhancing overall efficiency.

1. Energy Efficiency & Operating Costs

Worn or failed seals cause leakage. To compensate for the loss in pressure and flow rate caused by leakage, the pump's motor must work harder, consuming more electricity and directly increasing operating costs. Improper sealing can also cause excess friction leading to overheating, accelerating wear on other components.

2. Maintenance Costs & Downtime

Seals gradually wear out due to the fluid's corrosiveness, operating pressure, and high temperature. Seal failure is a common cause of unplanned pump shutdowns and expensive repairs. Frequent seal replacement not only increases parts costs but also means production interruptions, leading to significant losses.

3. Product Quality & Safety Risks

For sensitive industries, seals are the last line of defense for product quality. Seal failure leading to contamination can cause entire batches of product to be scrapped, potentially triggering compliance issues and safety incidents with serious consequences.

1. Select Precisely:

Choose seal type and material (e.g., PTFE, ceramic, elastomers) based on fluid properties, temperature, and pressure. Prefer low-friction seals to save energy.

2. Monitor Proactively:

Regularly inspect for leaks, vibration, or overheating. Use predictive tools like vibration analysis or thermography for early fault detection.

3. Install Professionally:

Ensure correct alignment, surface finish, and torque during installation by trained technicians to avoid premature failure.

4. Lubricate Adequately:

Maintain proper lubrication and cooling in extreme conditions to minimize friction and prevent overheating.

Although small, seals are core components determining a pump system's energy consumption, maintenance costs, reliability, and safety, which is why sealless magnetic drive centrifugal pump designs offer a revolutionary alternative by eliminating leakage points. Understanding their importance and optimizing seal performance through correct selection, professional installation, and proactive maintenance can significantly improve the entire pumping system's efficiency, extend equipment life, and ultimately reduce costs and increase efficiency for businesses, ensuring long-term stable operation.

In the LUBOR PUMP selection process, expert seal configuration is an integral part. Simply share your detailed operational data and specific requirements—we'll tailor the optimal sealing solution for you, ensuring safe and highly efficient pump performance.